Services

Advice and needs analysis for the use of software to optimize technical processes

Using the right application can significantly improve a technical process in terms of speed and stability. The continuous process should always be the focus.

SoftART Zürich AG has many years of experience in the field of CAD automation, the parameterization of freeform surfaces and the automation of manufacturing processes.

In most cases there are no standard solutions, which is why individual advice and needs clarification are necessary. SoftART Zürich AG combines systematic analyzes, engineering knowledge and experience in software development. We support our customers from the project idea to the development of the project-specific solution to successful commissioning.

For more information, visit the pages of our competence areas:

CAD automation , design software , fabrication process automation

Development of tailor-made software solutions in the technical area

SoftART Zürich AG specializes in complex software solutions in the technical field. We are convinced that we can substantially improve many technical processes through the targeted use of software. By working closely with our customers, we can participate in the entire solution-finding process and accordingly deliver high-quality solutions.

Our strengths lie in the creation and processing of free-form surfaces. In doing so, we respond to the individual requirements of our customers and create tailor-made software solutions for optimal benefit.

For more information, visit the pages of our competence areas:

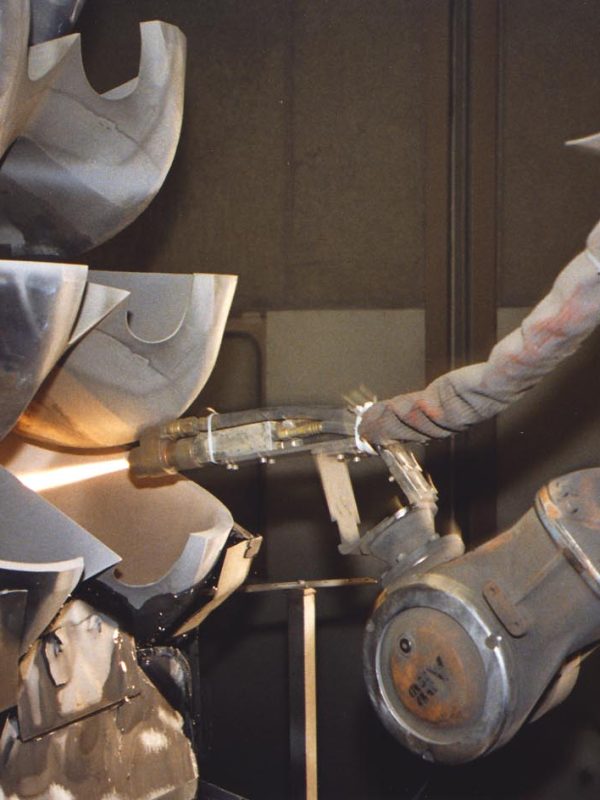

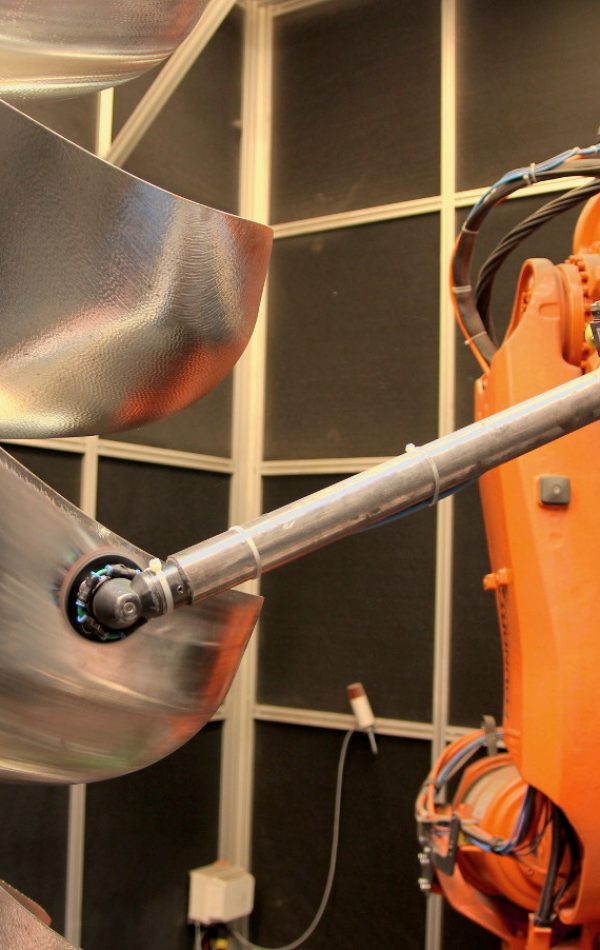

Automation of manufacturing processes through the targeted use of industrial robots

Robot-controlled production processes are important in industry. The high efficiency, accuracy and reproducibility are decisive factors. SoftART Zürich AG has specialized in programming industrial robots for very complex processing steps. Especially for the processing of components with irregular shapes, we have procedures and libraries with which the programming can be implemented particularly efficiently.

With fully automated offline programming, the robot movements within a complex component can be optimized with regard to the machining directions and process speeds, so that the best possible machining can be achieved. In addition, we can automatically detect and correct collisions between tool and component.

In the area of offline programming for industrial robots or in manufacturing process automation, we have experience from several projects that were the first in the world.

For more information, visit the pages of our competence areas: