Problem

The smoothest possible surfaces are required for Pelton turbines for optimum efficiency when generating energy from hydropower. Since milling for curved, smooth surfaces is very costly and time-consuming, the surface is still ground manually today.

solution

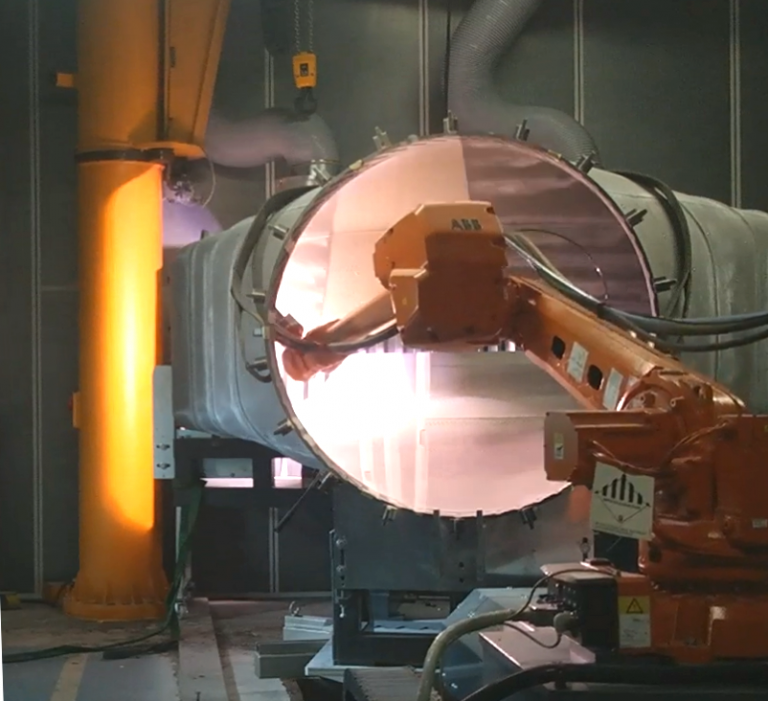

In the future, a robot will take over a large part of the grinding work. The robot works with a grinding wheel attached to an extension. The compact design allows the robot to reach areas that are difficult to access. The sandpaper is attached to the window with a Velcro connection, which allows the robot to automatically replace the window. An integrated force sensor enables conclusions to be drawn as to whether the pane is worn or whether it can still be used.

Special

In addition to saving time and costs, the robot can also achieve increased dimensional accuracy. In addition to constant contact pressure, the force sensor attached to the robot also allows the Pelton cup to be measured very precisely. Any deviations from the target geometry can be corrected by adjusting the grinding speed.

Robotic arm with extension

Grinding wheel in action