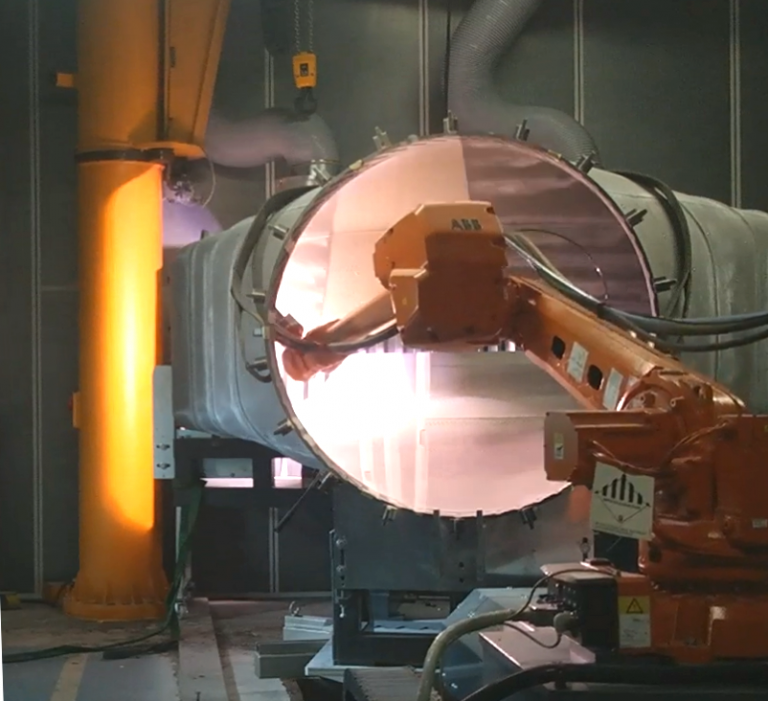

Problem

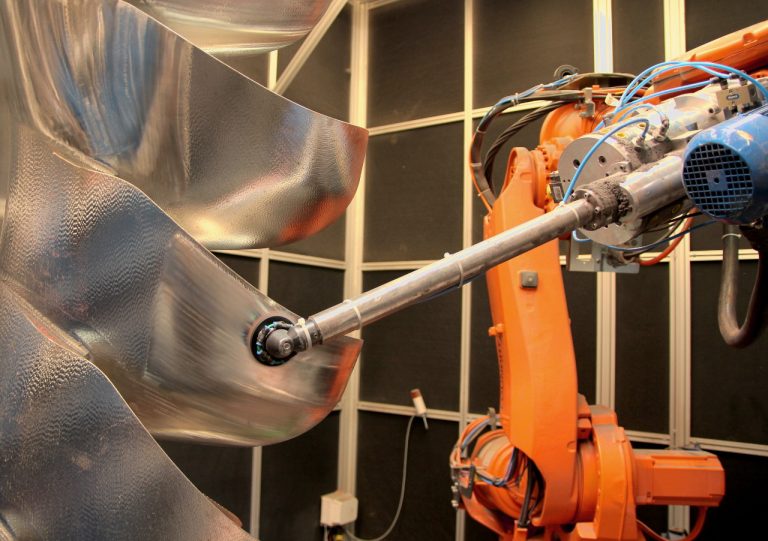

The hydraulic area of the Francis impeller is to be coated for a hydropower plant in India. The coating essentially helps against damage to the impeller caused by abrasion of the water. In order to achieve the highest possible quality of the coating, this impeller was coated with the new, efficient and powerful HVAF (High Velocity Air Fuel) process.

solution

The size of the component (4.4m diameter, 40t weight), the safety risk for the coater and the complexity of the movements make manual coating impossible, which is why an industrial robot has to be used.

The HVAF process places very high demands on the accuracy and uniformity of the layer application. In addition, a vertical application of the coating is desirable, but not possible everywhere due to collision problems. In addition, due to the size of the component, the robot reaches the limits of its driving range.

The solution to these three problems was essentially that after the calculation of the driving points, the collision calculation, the driving area check and the movement compensation were combined in a sophisticated algorithm.

Special

This Francis impeller was only the second in the world that was processed with the HVAF coating technology.