Projects

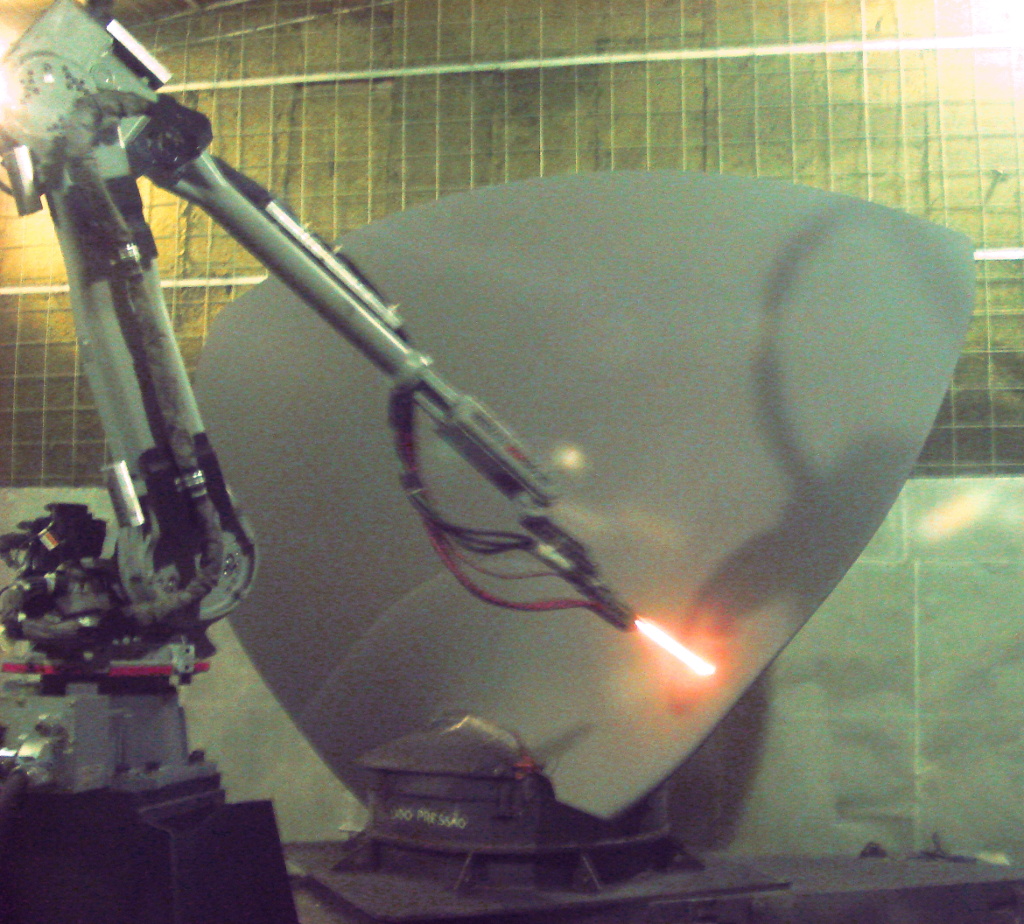

Coating of Kaplan Blade

Coating of Kaplan blades of the hydro turbines for Santo Antonio power plant (Brasil).

The coating against abrasion wear gets applied by a Motoman robot.

The complete motion program for the robot was calculated offline by SoftART.

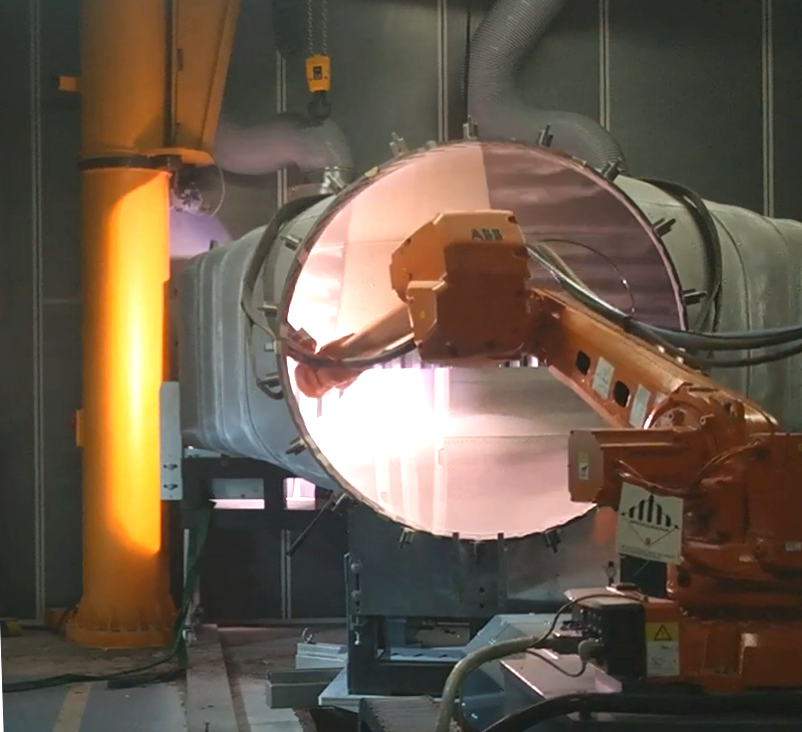

Coating of Hot Gas Casing

The Hot Gas Casing, which is a part of a gas turbine, must be coated on the complete inside surface to protect the metal sheets against heat.

Due to the size of the part, a 6-axis ABB robot mounted on a linear axis was used. The robot itself must move partially inside the work part and therefore the consideration of collision avoidance is crucial.

Based on the complexity of the task, the programming of the robot paths is only possible with offline methods.

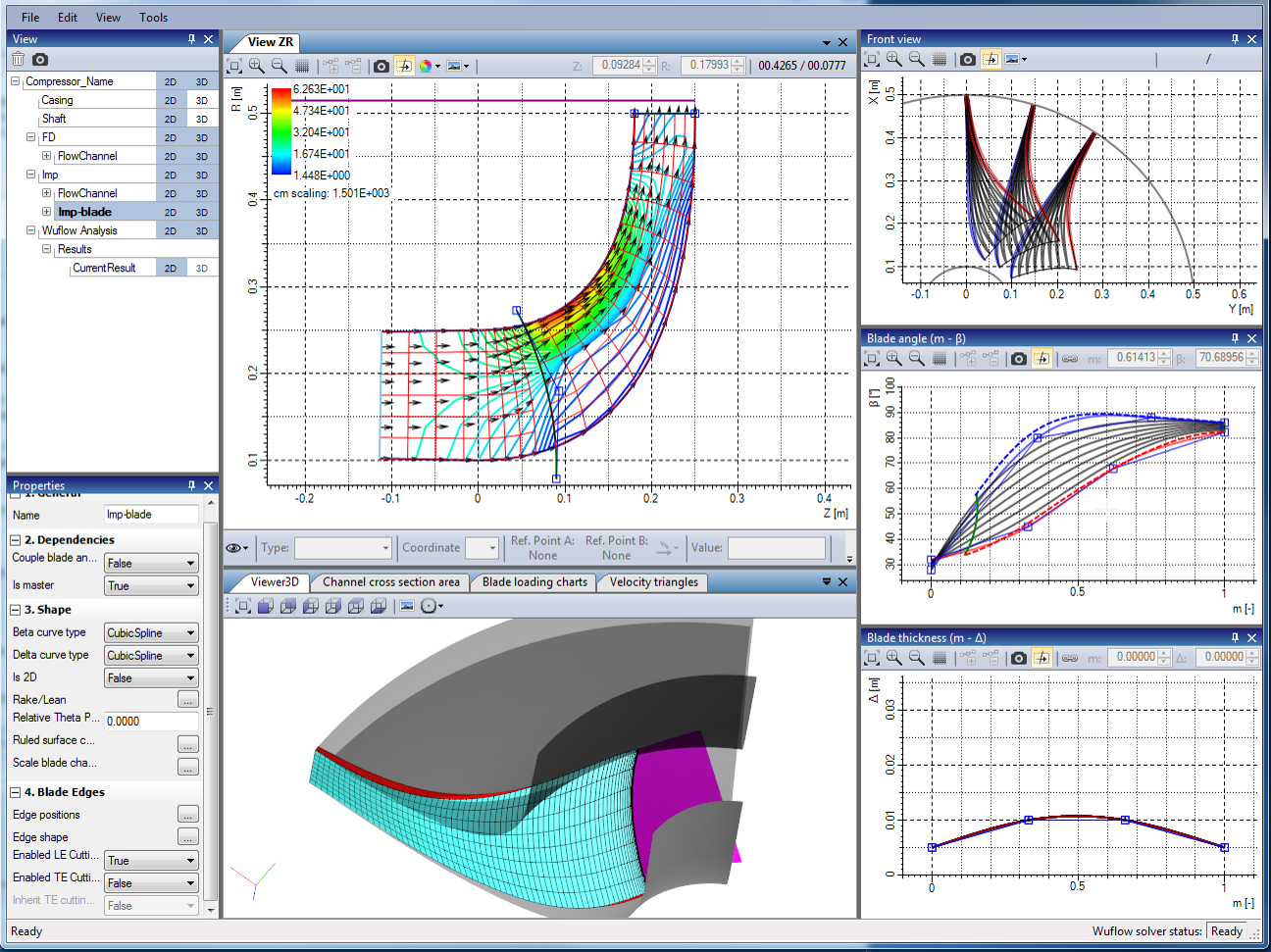

Blade Design Software

Aerodynamic profile design for turbomachinery is a highly complex and iterative process. A compressor blade consists of several parts that have tomatch each others geometric and aerodynamic properties.

The application allows development of single blades and whole compressor stages consisting of several rotor and stator blades in a unified user interface. All blade parameters can be edited interactively and the resulting geometry is always displayed live.

SoftART did the complete software development as a service for the customer.

Grinding Robot

The quality of the surface of hydro turbines, especially Pelton runners, is crucial for high efficiency. The surfaces must have a small roughness and uniform shape.

To achive high quality, it's best to use a robot for the grinding process. The robot can control the speed, contact pressure and movement strategy to use the grinding disc always in its ideal working range.

SoftART has developed a grinding robot system, using a standard 6-axis robot with force control and grinding tool attached. A software on an external computer calculates the movement paths, loads it to the robot controller and controls the complete process.